G7 ordinary high voltage inverter

- VOGA

- CHINA

- According to customers requirement

- 10--50 pcs/day

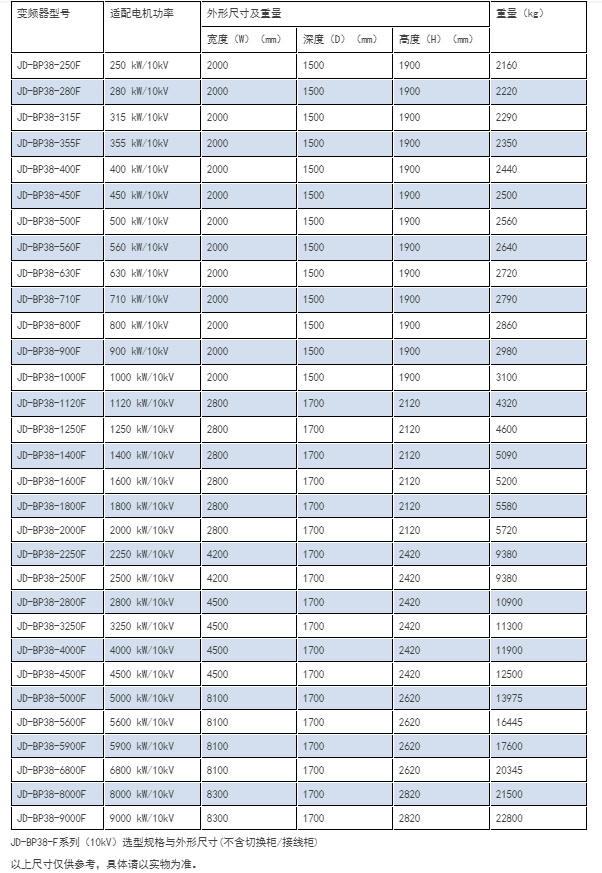

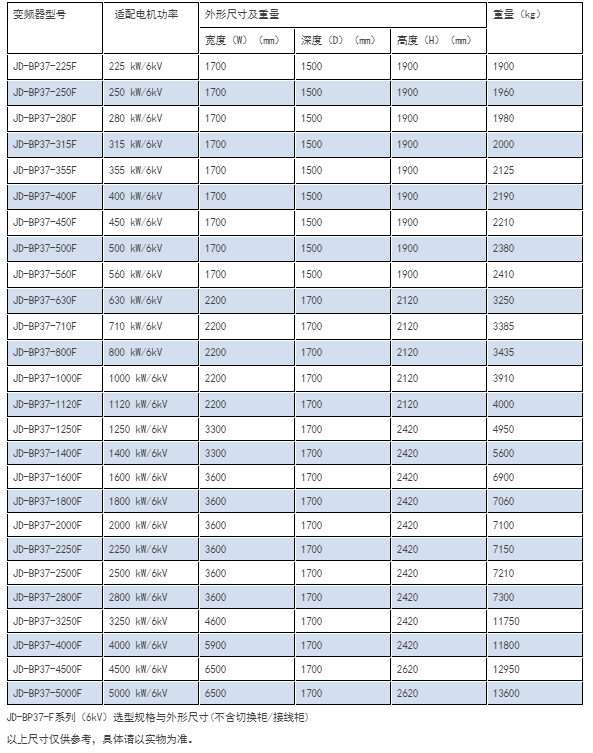

JD-BP37/38 series of high-voltage variable frequency speed regulation system, with high-speed DSP as the control core, adopts space vector technology, power unit series multi-level technology and other advanced control technologies, with high reliability, easy operation, high performance, small size The volume is the design goal to meet the needs of users for various load speed regulation, energy saving, and production process improvement. It is a high-high voltage source inverter. Its harmonic index is much smaller than the national standard of IEE519-2014, the input power factor is high, and the output waveform quality is good. It is unnecessary to use input harmonic filter, power factor compensation device and output filter; there is no additional heating and motor caused by harmonics. Torque pulsation, noise, common mode voltage and other issues can be applied to two/four quadrant synchronous motors (including permanent magnet synchronous motors) and asynchronous motors.

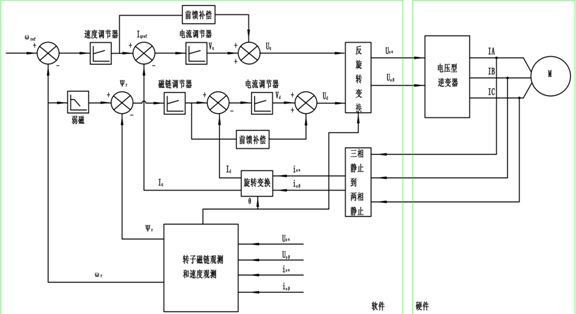

1. Vector control, fast response

By measuring and controlling the AC motor stator current vector, the excitation current and torque current of the AC motor are respectively controlled according to the principle of field orientation, so as to achieve the purpose of controlling the AC motor torque. The starting torque is large, the torque dynamic response is fast, the control accuracy is high, and the load capacity is strong. It can drive synchronous or asynchronous motors, especially suitable for impact loads such as ball mills, belt conveyors, and compressors.

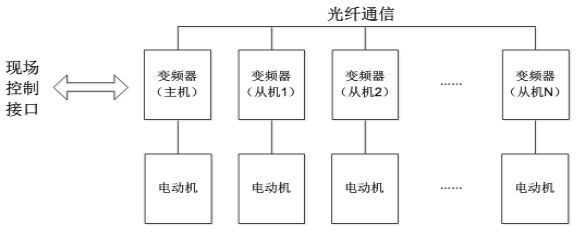

2. Multi-machine linkage, power balance

The inverter has a master-slave control function, and multiple inverters can form a master-slave control network through a data bus. Set one of them as the master and the others as the slaves. The master collects the status information of each slave in real time and sends the frequency and torque commands to each slave at the same time to realize the power balance and comprehensive control of each inverter. This technology is suitable for applications requiring power balance control such as belt conveyors and friction hoists.

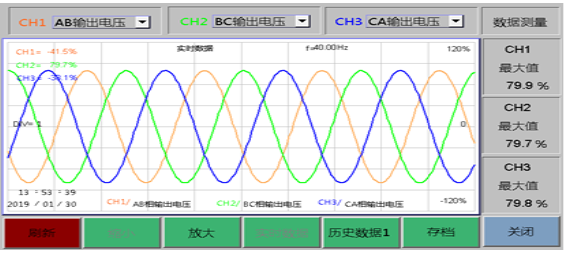

3. Comprehensive waveform display and record

The main control system monitors the input current, voltage, output voltage, and current in real time, and realizes the display of its waveform. It can also analyze the harmonics of each phase voltage and current, which helps the user to master various power parameters of the equipment.

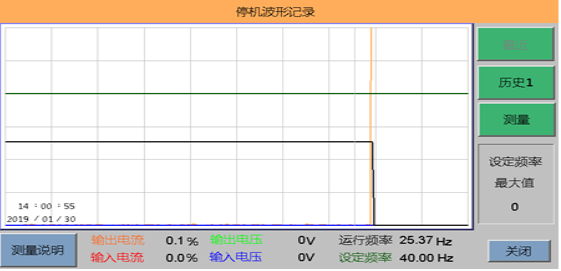

4. Black box function, intelligent analysis

The equipment has the function of automatically recording the operating status and display, and can view the output current, output voltage, set frequency, operating frequency, input current and input voltage values of a total of 200 points (100ms) before and after the protection, which is convenient for daily maintenance and rapid abnormal diagnosis .

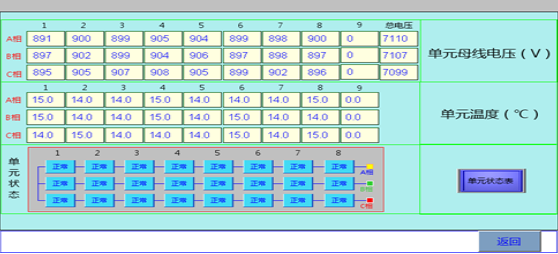

5. Temperature segmentation, early warning

The main control system monitors and displays the temperature of each power unit in real time. When the temperature of multiple units exceeds the set alarm value, it will give an audible and visual alarm to prompt the user to deal with problems such as the trip of the cooling fan and the blockage of the filter in time.

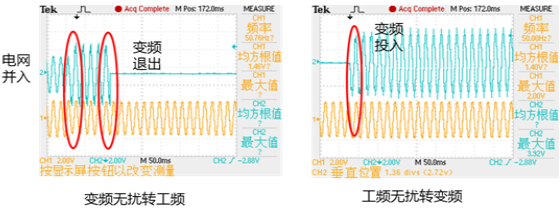

6. Undisturbed switching, avoid impact

Frequency conversion cut power frequency: The frequency converter brings the motor to the power frequency frequency, detects the frequency, phase and amplitude of the power frequency grid, and then adjusts the frequency converter output to be the same frequency and phase as the power frequency. After the adjustment is complete, connect the motor to the grid and disconnect the inverter. Power frequency cut frequency conversion: First, the frequency converter detects the frequency, phase and amplitude of the power frequency grid, and directly outputs the corresponding voltage vector to the motor after the frequency converter cuts in, and finally exits the power frequency. This technology can meet the needs of multi-motor integrated control and large-capacity motor soft start. The maximum current is less than or equal to the rated current, and it can truly achieve fast soft switching and no large current impact.

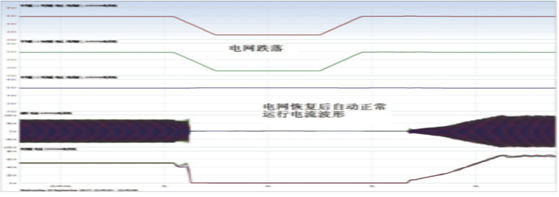

7. High and low crossing, no fear of fluctuations (100%-0%)

When the user's main power supply instantaneously cuts off, instantaneously drops, or the factory power grid is switched, the inverter can ensure that it can automatically operate normally after the grid is restored within a limited time, and enhance the adaptability of the grid. It can adapt to Uo (100%-0%) grid drops of different depths.

8. Other technical features Dual-loop control power supply is stable and reliable. High power density: small unit size, modular design; compact structure, small space occupation. DC braking technology: When the motor is rotating (below 10Hz), the DC braking current can be applied to force the motor from the rotating state to the stopped state. Current limiting technology: When the inverter is turned on and running, if the current exceeds the limit value, the increase in current is limited by frequency reduction until the current is less than the limit value, and the inverter returns to the normal operating frequency. Overvoltage stall technology: During the frequency reduction process of the inverter, when the motor generates power and the bus rises, the inverter will automatically extend the frequency reduction time to prevent the shutdown problem caused by the bus overvoltage. Multiple control methods: select local control, remote control box control, DCS control; support MODBUS, PROFIBUS and other communication protocols; frequency setting can be given on site, communication, etc.; support frequency preset, acceleration and deceleration functions. Acceleration/deceleration adaptive function: the inverter adjusts the acceleration time or limits the motor operating frequency according to the current load current of the motor, thereby limiting the current and realizing the function of no current during acceleration. During the frequency reduction process of the inverter, the frequency reduction time is adjusted according to the size of the bus voltage, so as to achieve the function of overvoltage during the frequency reduction process.

A: We are Integration of industry and trade, sales of the special equipment, petrochemical refining plant, excavator, electric shovel, tunnel boring machine,shield tunneling machine, electric heavy truck,large casting and forqing,wind power generation, petroleum storage tank, large boiler, frequency converter,energy storage type converter,nuclear power equipment,breathing machine. Our factroy is ...more